Booth #N6149 - Schmalz Electrical Vacuum Generator CobotPump (ECBPi) - Intelligent electrical vacuum generator for handling airtight and slightly porous workpieces

Contributed by | SCHMALZ

Tell us about your company.

The wide range of products in the Vacuum Automation unit includes individual components such as suction cups and vacuum generators, as well as complete gripping systems and clamping solutions for holding workpieces, for example in CNC machining centers. The Handling Systems unit offers innovative handling solutions with vacuum lifters and crane systems for industrial and handicraft applications. The intelligent solutions make production and logistics processes more flexible and efficient, while also preparing them for the increasing trend toward digitalization.

Your company will be exhibiting at PACK EXPO, what is it that makes this an important event for your company?

PackExpo offers us the largest audience to tangibly show off our packaging - cups, generators, area gripping systems and manual handling systems to. In addition the show is a great forum for our engineers to discuss solutions to challenging applications.

Highlight a 2 or 3 products you will be showcasing at the event?

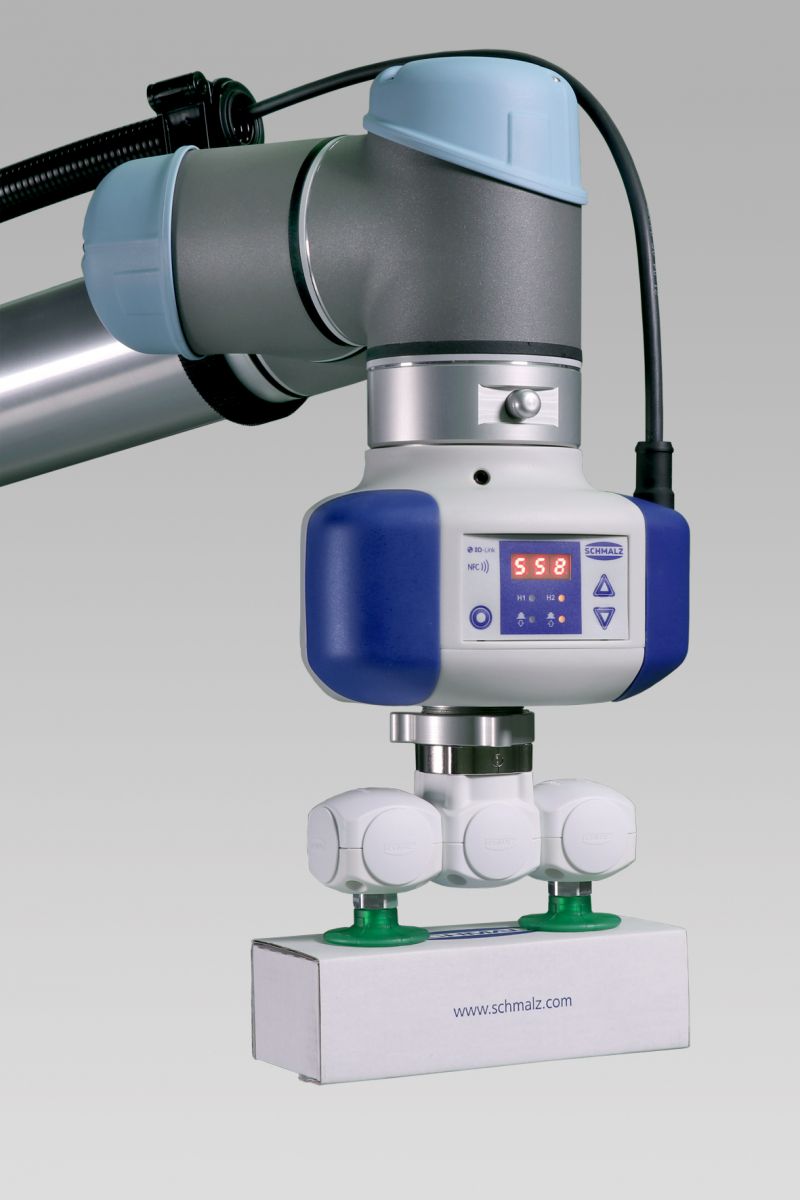

NEW! Schmalz Electrical Vacuum Generator CobotPump (ECBPi)

- Intelligent electrical vacuum generator for handling airtight and slightly porous workpieces

- Integrated interface for controlling and monitoring the handling process

- For use in mobile robotics, fully automated small parts handling and stationary handling tasks

NEW! Schmalz Cobot Gripper (MRK)

- Ideal for stationary handling tasks with collaborative robots

- For all applications in the field of intralogistics (e. g. end-of-line packaging, pick & place applications)

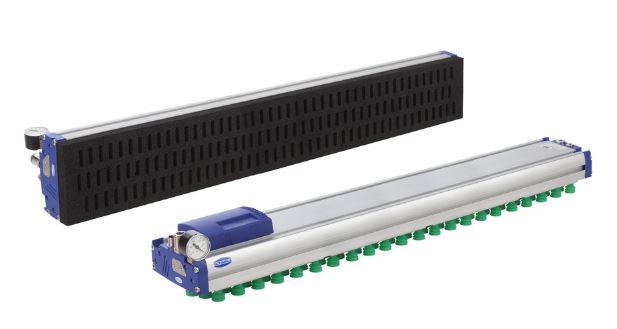

Area Gripping Systems (FXP)

- Universal gripper with integrated, pneumatic vacuum generation, for handling workpieces regardless of size, geometry, material and surface

- Handling of workpieces made from various materials, such as wood (coated or unplaned), packaging (boxes, bags or cans), metal sheets, glass, plastics, CFRP, etc.

- Handling of porous workpieces, workpieces with gaps or undefined pick-up position

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see?

Our booth staff is most interested in seeing the latest and greatest in The Innovation Stage.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. The process of packaging is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Many of our longstanding generator, switch and monitoring products have been updated in recent years to include IO Link and NFC capabilities. We feel strongly that this is essential to today’s manufacturing centers and we’re eagerly involved in the advancements that will come.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product