When you visit us at booth 3323 , you will be able to experience a live demo of our robotic tool changer system, as well as live presentations throughout each day.

Q&A with | Stäubli Group

Tell us about your company. (Source: About Stäubli Group)

Stäubli is a global mechatronics solution provider with four dedicated Divisions: Electrical Connectors, Fluid Connectors, Robotics and Textile, serving customers who want to increase their productivity in many industrial sectors. We are an international group settled down in almost 30 countries on 4 continents with our own teams close to our customers. "Our global workforce of 5500 shares a commitment to partnering with customers in nearly every industry to provide comprehensive solutions with long-term support. Originally founded in 1892 as a small workshop in Horgen/Zurich, today Stäubli is an international group headquartered in Pfäffikon, Switzerland.

Your company will be exhibiting at AUTOMATE, what is it that makes this an important event for your company?

Automation has deep roots in the automotive and plastic industry, which are 2 core markets Stäubli has been part of for decades. Automate will be a great opportunity to connect with old and new clients, as well as to see new trends and applications and their demands for the industry now and in the future, as well as giving us the opportunity to show to our customers and partners the newest innovations in line with their demands.

What makes your booth a must visit for AUTOMATE Attendees?

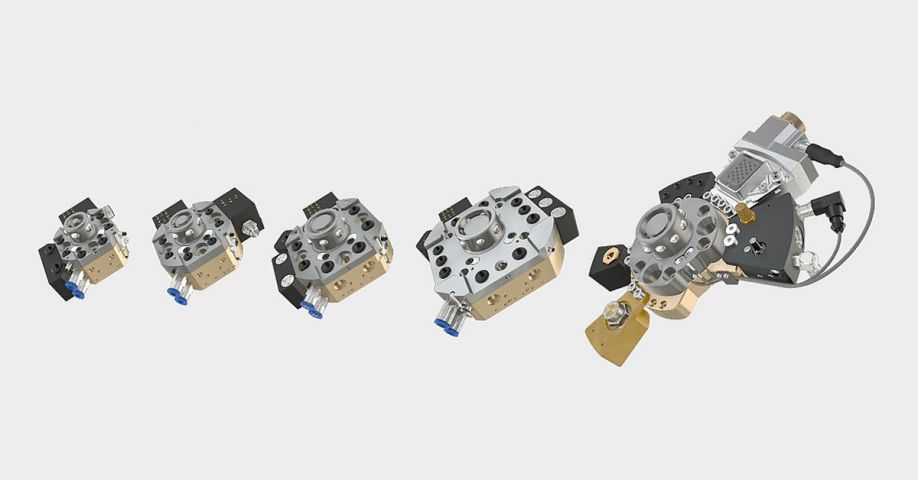

As one of the leading manufacturers of quick connector systems, Stäubli covers connection needs for all types of fluids, gases and electrical power. Our standard and specialized products, including quick and dry disconnect couplings, multiconnection solutions, safety break-away couplings, tool changers and quick mold change systems, combine performance, quality, safety, dependability and durability. The high quality and performance of our systems and components are very demanding in this new manufacturing era, where sustainability and efficiency have highest priority. When you visit us at booth 3323 , you will be able to experience a live demo of our robotic tool changer system, as well as live presentations throughout each day.

AUTOMATE has many educational sessions, forums & Demo’s, is your company involved in any of them this year?

Not this year.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

Over the last couple of years, Automation trends have redefined the way of manufacturing today. Personally, I look forward to seeing new applications and developments as well as having good conversations with exhibitors and participants.

The factory floor is undertaking rapid advancements, be it automation, robotics, machine vision or data. Automation Technology is a huge part for many manufacturers, give us an idea on how your company and product is being utilized now in the smart factory.

Stäubli offers connection solutions tailored to the requirements of each industry. While the need for optimum efficiency, high productivity and superior quality are universal, every industry demands unique technological solutions. Stäubli engineers focus on developing connection solutions, including tool changers for robots, quick couplings, multi-couplings,

Give us your thoughts on what the future holds for manufacturers and automation technology (Source: 2021 IFR Report)

This will likely be the decade where robotics and automation will enable the transformation businesses need and where robotics and automation will change the way we work. Likewise, a world will be created where people work side-by-side with advanced robots, collaborating on complex tasks, improving the nature of work and helping to advance society. When we fully harness the power of robotics, to unlock growth in new sectors of the economy and when we make work more rewarding, safer, healthier – and more productive for people.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product