"Robotics is About People - Why You Need Change Management"

Success in robotics is fundamentally about people, which is why change management is crucial for any organization considering RPA implementation.

Fizyr, Cognibotics and Zivid Deliver World's Fastest Automated Bin Picking Solution

The Zivid 2+R-series camera captures true-to-reality point clouds, even when presented with shiny and transparent objects, in under 150 milliseconds ensuring it does not limit the cycle time of the Cognibotics HKM1800

Stretch Helps Gap Inc. Deliver for Its Customers

By having Stretch take on the physically demanding task of unloading trailers stacked floor to ceiling with boxes, the company has reduced injuries, lowered turnover, and watched employees get excited about automation intended to keep them safe.

A3 Releases Vision for a U.S. National Robotics Strategy

Strategy outlines key policy priorities, including establishing a central Robotics Office and Robotics Commission, to strengthen U.S. competitiveness in robotics, drive innovation, and support workforce development

NGen, Humber Polytechnic, and Festo Didactic Showcase Canadian Skills at Hannover Messe 2025

NGen, Festo Didactic and Humber Polytechnic, a leading Canadian post-secondary institution known for its career-focused, hands-on approach to education, are partnering to demonstrate the strength of Canadian mechatronics skills at Hannover Messe.

Automation and Humans: Will We Be Replaced?

Take a warehouse worker who spends a significant amount of time moving boxes from point A to point B as an example; automation can handle this aspect of the job instead, freeing that worker to focus on more complex tasks like inventory management and quality control.

RightHand Robotics Announces Strategic Investment from Rockwell Automation

Combining RightHand Robotics' innovative robotic piece-picking technology with Rockwell Automation's industry-leading expertise, the collaboration aims to offer smarter, more efficient, and fully integrated automation solutions for supply chains worldwide.

Robotic Software Market is Poised to Surpass USD 150 Billion by 2034

With businesses across industries striving to optimize operations, increase efficiency, and reduce costs, robotic software is becoming a crucial component of modern industrial and service applications.

'Eyes, hands, brains and mobility' will define robotics beyond 2025

Building on 50 years of robotics leadership, 2025 marks the beginning of a new era of AI application in industrial robotics. Launch of new ABB Robotics brand film unveils new levels of versatilty for robots to do more tasks, in more places.

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

This brand-new regional show promises to connect industry leaders, innovators and decision-makers while showcasing cutting-edge technologies that will shape the future of manufacturing across more than 40 vertical markets.

Mobile Robot Charging Station Market to Hit $38 Bn by 2031 at 15.9% CAGR | Persistence Market Research

This surge is fueled by automation in industries such as manufacturing, logistics, and warehousing. North America is projected to lead with a 15.4% CAGR, while Asia Pacific is set to grow at 18.3%, driven by rapid industrialization.

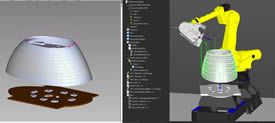

Enterijer Mesicki and RoboDK Transform Serbian Furniture Manufacturing with FANUC Robots

Furniture manufacturer Enterijer Mesicki has created a cutting-edge robotic solution for automated furniture production using RoboDK software and FANUC technology.

Top 5 trends for the AIoT industry in 2025

This year, we dive deeper into the trends driving AIoT, showing how they are reshaping industries and fostering a more efficient, secure, and sustainable future.

Dürr equips first BYD plant in Europe with sustainable painting technology

The painting lines will use Dürr's latest EcoRP series painting robot, available in both six- and seven-axis variants for interior and exterior painting.

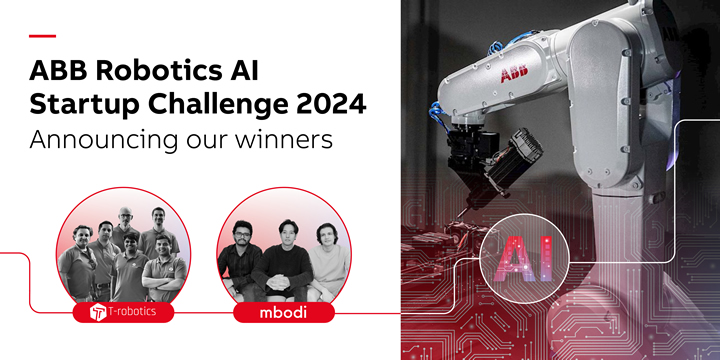

ABB Robotics names T-Robotics and Mbodi as AI Startup Challenge Winners

Startups T-Robotics and Mbodi selected to collaborate on conversational AI and adaptive learning robotics solutions . Both winners selected from over 100 global pioneers of next-generation automation technology.

Records 1 to 15 of 425

Factory Automation - Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Significantly enhanced servo performance, higher EtherCAT networking precision, richer servo operation capabilities, more feedback options, and certified smart Functional Safety. Elmo's industry-leading Platinum line of servo drives provides faster and more enhanced servo performance with wider bandwidth, higher resolutions, and advanced control for better results. Platinum drives offer precise EtherCAT networking, faster cycling, high synchronization, negligible jitters, and near-zero latency. They are fully synchronized to the servo loops and feature-rich feedback support, up to three feedbacks simultaneously (with two absolute encoders working simultaneously). The Platinum Line includes one of the world's smallest Functional Safety, and FSoE-certified servo drives with unique SIL capabilities.

.jpg)

.jpg)

.jpg)