Case Study Evaluation of an Auditory Alert for an Autonomous Mobile Robot

In this case study, we focus on the autonomous mobile robot (AMR), which can navigate and perform tasks in active environments without direct human control. Safe navigation and obstacle avoidance are fundamentally important for AMRs in the workplace.

Giving lens cleaning cloths a robotic hand - Robotic automation for textile processing

Here’s how Italian startup, Roboprint, partnered with TM Robotics, the distributor of Shibaura Machine robots, to develop an automated solution for the labour-intensive processes of detaching and handling eyeglasses fabric stock.

Jasper Group Using AMRs for Material Handling

Jasper Group turned to a systems integrator, Robotic Solutions, LLC, to help them consider using autonomous mobile robots (AMRs) for material handling in a plant of more than one-million square feet of manufacturing space.

Machine Vision meets every taste

Ensuring safety and accuracy of correct packaging is a high priority in the food industry. In addition to the packaging quality, the high variation of different packaging and labeling is also a challenge.

Global cricket ball manufacturer uses automation with a vision system for efficiency and upskilling

The plan was to place the full trays of cricket ball covers into the dispenser, feeding trays automatically to the TVL700 robot to load and unload the trimming machine. This requires only one operator to load a set of trays every 20 to 25 minutes.

Chemical Manufacturing Leader Polysciences Partners With Formic to Introduce Automation To Their Production Process

With a unique capability of offering concept-to-commercialization services to their clients, making continuous production improvements for commercialization is a key focus.

Customer Renews Contract as Cyngn's Autonomous Vehicles Yield 4x Efficiency Gain

USC has enjoyed tremendous growth over the three decades it's been in business. The company has become familiar with the hurdles intrinsic to manufacturing and distribution: supply chain disruptions, soaring labor costs, and the relentless pursuit of operational efficiency.

Delica Drives Efficiency with AGV Installation

Delica selected a Stöcklin AGV with BlueBotics’ ANT navigation technology to automate their materials handling between production and logistics.

The World's First Dual-Arm Autonomous Robotic Sanding Cell

GrayMatter Robotics and BetterWay Products Inc. Revolutionize Marine Manufacturing with Cutting-Edge Robotic Innovation

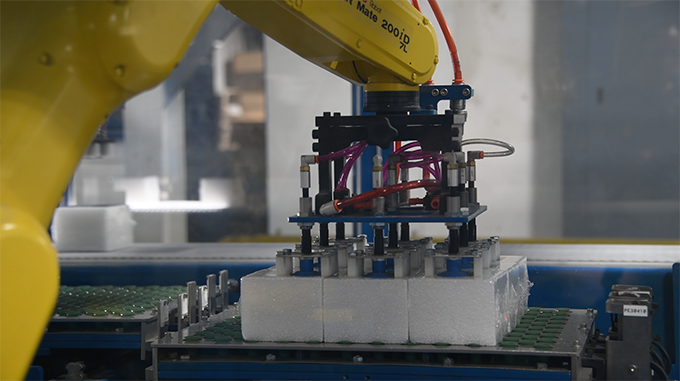

Insights from Brenton Engineering Company

Equipment Flexibility Key to Accommodating Changing Applications , The Upside of Automation on Your End-of-Line Operation, The Value of Project Management

FORVIA

Currently in the PÃsek location, 14 MiR robots are deployed. 7 of them, heavy duty MiR robots, mainly MiR600s, work in the area of finished goods, bringing empty pallets to the assembly lines and picking up full pallets to the logistics area.

Universal Robots - Centercode Case Study

Universal Robots sought a partner to help transform their traditional, ad hoc, check-the-box user testing program into an efficient source of actionable product feedback to give them a significant edge on their competition.

COMPUTER VISION AND ROBOTICS EXPAND INDUSTRIAL CAPABILITIES

How can industrial robots gain new abilities that can increase their operational value while remaining safe and secure in a factory collaborating with humans?

Machine Automation Taken to the Next Level

Around 20 million cutter blades for hair clippers and beard trimmers leave the Philips plant at Klagenfurt every year. In order to make the complex grinding process as efficient as possible, the company has opted for a pioneering automation concept, where the loading of the machine and the delivery of the parts is fully automated.

FT-Produktion Boosts Output Capacity Without Adding Personnel by Employing Combination of Collaborative Robots and Robot Grippers

â€�"We chose a combination of solutions from OnRobot, Universal Robots, and EasyRobotics because they are easy to program, and the investment will pay for itself in just nine months. It’s one of the best business decisions we’ve ever made.â€

Records 1 to 15 of 52

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.